Docket #: S10-333

Manufacturing Method for Synthetic Gecko-Inspired Adhesives

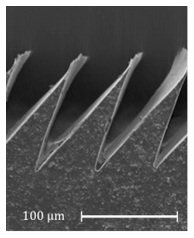

Stanford researchers have developed a new manufacturing method for creating inexpensive, directional dry adhesive materials, suitable for applications such as climbing robots, human climbing and manufacturing applications. This method is more controllable, more repeatable and has a higher yield than current lithographic methods while producing arrays of features with similar quality and performance.

This invention is an advancement of the technology presented in S06-091 "StickyBot - Climbing with dry adhesives" developed by Prof. Cutkosky's research team at the Stanford Biomimetics and Dexterous Manipulation Lab.

Figures:

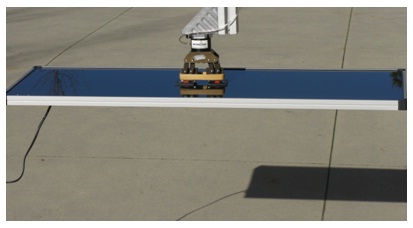

A custom end-effector using the adhesives being used to support a large solar panel.

Stage of Research:

Applications

- Dry adhesives have many applications, including climbing humans and robots, medical devices and manufacturing processes involving the handling of delicate or sensitive materials.

Advantages

- Less expensive and more controllable than existing lithographic processes for making similar molds

- Allows greater flexibility with respect to the micro-scale feature geometry, mold size, and mold material

- Better performance than previous methods

Publications

- US Patent Application 20120295068

- Day, P., Eason, E., Esparza, N., Christensen, D., and Cutkosky, M., "Micro-Wedge Machining for the Manufacture of Directional Dry Adhesives," ASME J. Micro Nano-Manuf. 1, 011001 (Mar 22, 2013).

Patents

- Published Application: 20120295068

- Published Application: 20160046043

- Issued: 9,908,266 (USA)

Similar Technologies

-

StickyBot - Climbing with dry adhesives S06-091StickyBot - Climbing with dry adhesives

-

Layered electroactive polymers for robust and reliable variable-stiffness suspensions in robotics, prosthetics and autonomous vehicles S15-122Layered electroactive polymers for robust and reliable variable-stiffness suspensions in robotics, prosthetics and autonomous vehicles

-

Haptic Interface with Variable Stiffness and Deformable Geometry S12-428Haptic Interface with Variable Stiffness and Deformable Geometry