Docket #: S11-410

Anti-Reflective Nanowire Electrodes in Photovoltaics

Engineers in Prof. Fritz Prinz's laboratory have developed a low cost, scalable method to fabricate anti-reflective, highly conductive metal silicide nanowires electrodes for photovoltaic cells. This single-crystalline material effectively scatters light across a wide range of wavelengths to efficiently absorb light across the solar spectrum. Also, because the nanowires are highly conductive, they can serve as back electrodes or ohmic or Schottky diodes to facilitate charge transport in a variety of architectures.

The nanowires are fabricated on a flexible foil substrate with a scalable bottom-up manufacturing process that can be easily tuned to control diameter and density. This technology could be used for large-scale manufacturing of nanowire electrodes for highly efficient photovoltaic or photoelectrochemical cells.

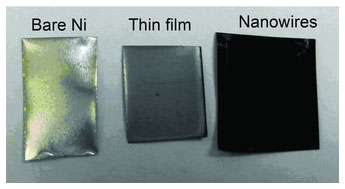

Photograph of three sample materials, showing a dramatic decrease in reflectivity of the nanowire sample - across wavelengths between 350-1100nm, the reflectance measured with an integrating sphere was 45-70% for Bare Ni, 20-40% for Thin film, and 1% for Nanowires.

Stage of Research

The inventors have used this fabrication technique to produce single crystalline Ni2Si/NiSi nanowire on an Ni foil substrate. The nanowires had broadband reflection suppression to levels below 1% from 350 nm to 1100 nm and resistivity of 10-4 Ω-cm. The inventors continue to explore combining these nanowire arrays with coatings deposited by atomic layer deposition.

Applications

- Photovoltaic cells - back electrode material that could be incorporated into a variety of architectures and material combinations

- Photoelectrochemical cells

- Diodes - contact for Schottky or ohmic diodes

Advantages

- Excellent light-scattering - highly anti-reflective with broadband suppression of reflection to levels 1% for 350 nm to 1100 nm

- Highly conductive - resistivity of 10-4 Ω-cm

- Simple, scalable fabrication:

- bottom-up thermal decomposition (no lithography, etching or catalysts)

- tunable diameter and density of nanowire

- potential integration into roll-to-roll processing

- Low cost, flexible substrate

Publications

- N. P. Dasgupta, S. Xu, H. J. Jung, A. Iancu, R. Fasching, R. Sinclair and F. B. Prinz, "Nickel Silicide Nanowire Arrays for Anti-Reflective Electrodes in Photovoltaics", Adv. Funct. Mater., vol. 22, pp. 3650-3657, 2012.

Patents

- Published Application: 20130149860

- Issued: 9,166,074 (USA)

Similar Technologies

-

Broadband, polarization-independent, omnidirectional, metamaterial-based antireflection coating for solar cells S16-418Broadband, polarization-independent, omnidirectional, metamaterial-based antireflection coating for solar cells

-

Nanostructured material for high efficiency single junction solar cells S12-012Nanostructured material for high efficiency single junction solar cells

-

Strong and stable doping of carbon nanotubes and graphene by MoOx for transparent electrodes S12-107Strong and stable doping of carbon nanotubes and graphene by MoOx for transparent electrodes