Docket #: S22-367

3D fabrication of high resolution negative spaces

Researchers in the DeSimone Research Group have developed a high-resolution injection Continuous Liquid Interface Production (iCLIP) 3D printing process. This innovative technique utilizes synergistic control of optical systems and fluid mechanics to achieve micrometer XY and Z resolution, surpassing the limitations of traditional stereolithographic printing. By effectively displacing trapped resin in microchannels, which are prone to UV accumulation and print-through, using an oxygenated or non-reactive agents, the iCLIP process breaks the requirement of low UV penetration depth to resolve high-resolution micro-structures. Thus, iCLIP can significantly expand the material options available for 3D-printing microsystems. This approach can be used with CLIP 3D printing of negative structures, as well as traditional vat-based Stereolithography (SLA) 3D printing, and has the potential to replace photolithography as the fabrication method of the microelectronic, microsensor and microfluidic industries.

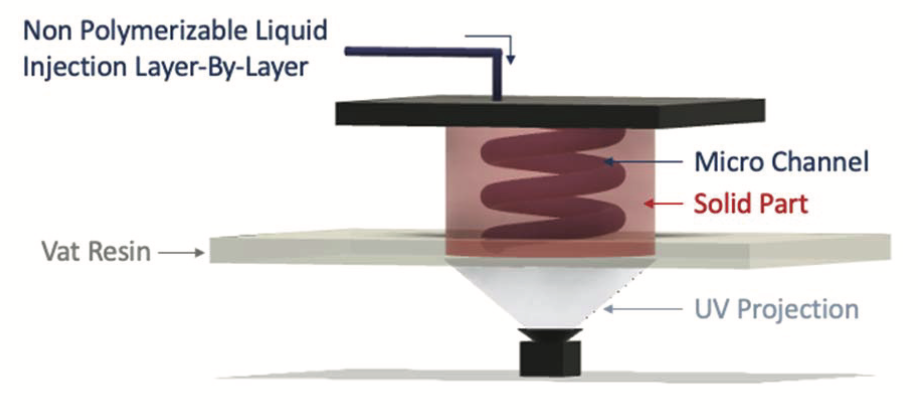

Figure 1 injection CLIP method to preserve negative structures inject a non-reactive fluid to flush out trapped resin to preserve negative structures. (Image courtesy the DeSimone Research Group)

Stage of Development – Proof of Concept

DeSimone Research Group has demonstrated proof of concept for the technique and plans further technology refinement.

Applications

- 3D Printing (CLIP 3D printing and traditional vat-based SLA 3D printing) of high resolution negative spaces – potential replacement of photolithography as the fabrication method of the microelectronic, microsensor and microfluidic industries.

Advantages

- High scalability

- High print speed/throughput

- Precise with uniform surface smoothness

- 3D design capability

- Robust internal structures

Related Links

Patents

- Published Application: WO2024086096

Similar Technologies

-

Denoising WaveY-Net: An ultra-fast, auxiliary neural network enhanced surrogate field solver S22-445Denoising WaveY-Net: An ultra-fast, auxiliary neural network enhanced surrogate field solver

-

Fully elastic dielectric polymer for photolithography of flexible electronics S17-306Fully elastic dielectric polymer for photolithography of flexible electronics

-

Faster Multimaterial 3D Printing with High Viscosity Resins (iCLIP) S22-128Faster Multimaterial 3D Printing with High Viscosity Resins (iCLIP)