Docket #: S11-162

Compact, High Resolution Rotary Position Sensor

This compact, low-cost, high resolution angular position sensor is designed to improve the movement of rotary joints. The capacitive sensor, which includes two flat discs patterned with conductive material can be packaged in tight spaces. The sensor produces a highly robust, friction-free angular measurement using non-contact sensing technology. The sensing discs can be as thin as a few sheets of paper and have a center cutout to allow the passing of a shaft or cabling. The sensor is alignment insensitive - capable of rejecting motion noise in all directions not intended to be sensed. This allows for high precision angular measurements with low precision mounting. The sensor is also completely shielded to reject environmental electrical noise. Larger sensors or sensors with improved readout electronics will produce even higher resolution. The sensor is applicable in almost any field where angular measurements are required, such as robotics, vehicles, industrial automation, toys or game consoles.

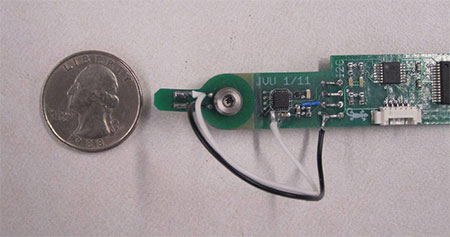

Rotar Sensor Prototype

Stage of Research

The inventors have built prototype sensors with noise-free resolution on the order of 12,000 counts per revolution for 0.5” diameter and 60,000 counts per revolution for a 1”' diameter sensor (significantly higher than any other technology with similar form factor and cost). The sensor's high resolution also opens the door for robust, low-cost, high resolution torsion sensing and prototypes are under development.

Applications

- Robotic joints - for direct joint position sensing

- Automobiles - for traction control sensing or steering wheel position sensing

- High volume production - low cost could make this sensor useful in cost-sensitive markets such as toy manufacture, game consoles and industrial automation

Advantages

- Compact - sensor is flat and thin and can be made as small as a fraction of an inch. Prototypes as thin as a few sheets of paper have been demonstrated.

- Reliable - significantly less precision required for mounting than with competing technologies.

- Robust - uses a non-contact sensor, so there are no sliding contacts to wear out nor friction introduced to the joint.

- Alignment insensitive - the sensor is sensitive only to relative rotation of the discs about their center axes so signals from unaligned plates, or any motion not about the center axes (tilt, and translation in both the normal and lateral directions) are cancelled thus producing little to no signal on the output.

- High resolution - better resolution than current sensors of similar size and cost (over 60,000 counts per revolution demonstrated on 1” diameter prototype)

- Cost effective - lower cost than traditional position sensors

- Customizable - inner/outer diameter as well as thickness are easily adapted to a given application

Patents

- Published Application: 20130093439

- Issued: 8,847,611 (USA)

Similar Technologies

-

"Black Box" for Automated Vehicle Data S20-320"Black Box" for Automated Vehicle Data

-

Magnetically Actuated Photonic Crystal Sensor S10-227Magnetically Actuated Photonic Crystal Sensor

-

No-switching AC magnetic Hall-effect measurement method S19-035No-switching AC magnetic Hall-effect measurement method