Docket #: S21-096

Environmentally Friendly Fertilized Water Production via Cold Plasma

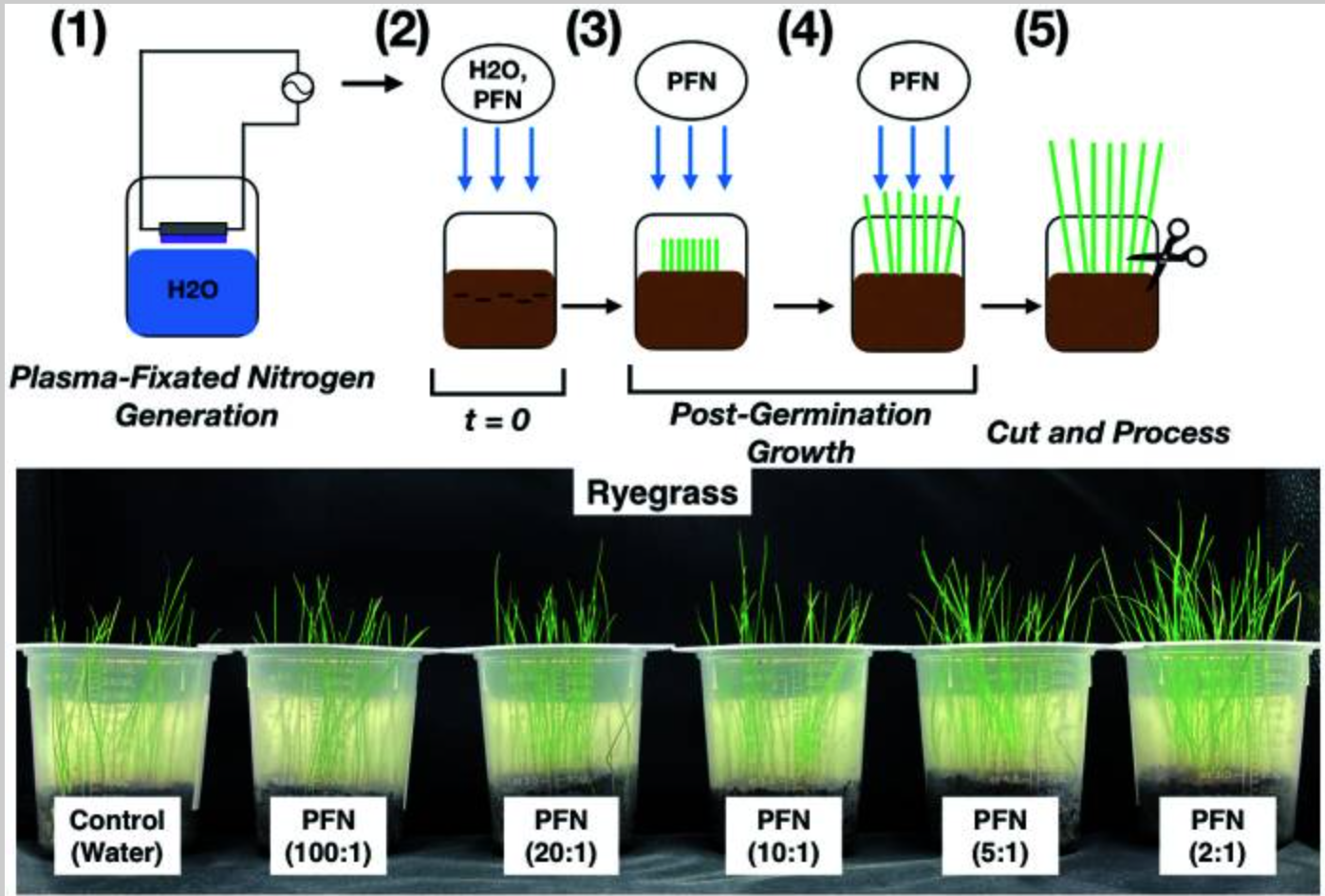

Stanford Plasma Physics Lab researchers have developed a scalable system to manufacture fertilize water, or plasma fixated nitrogen (PFN) in water, using cold nonequilibrium plasma. Current fertilizer manufacturing use roughly 1% of the world's total energy production and contributes 1% or more of the world's CO2 emissions. We have our PFN's bio-uptake on turf grass. Turf grass, used in residential and commercial lawns, golf courses, and recreational and sports fields, is one of the largest irrigated crops in the United States. The Stanford Plasma Physics Lab system (figure 1) uses a non-thermal plasma (cold, electrified air) near a thin sheet of water to activate the water directly, infusing it with peroxynitrates, which have biostimulant properties. This portable, scalable, economically viable, plasma-fixated nitrogen fertilized water system is ideal for small agricultural facilities, specialty farms, hydroponic facilities, and indoor farms, as well as commonly used turf grass with no CO2 emissions and nearly zero carbon footprint when using electricity from renewable sources.

Figure 1 Effects of Nitrate Concentration on Growth for Plasma Fixated Nitrogen Fertilized Ryegrass. Plasma-fixated nitrogen solution diluted with industrial water growth efficacy comparison for dilution factors of 2:1, 5:1, 10:1, 20:1, and 100:1.

Image courtesy the Stanford Plasma Physics Lab

Stage of Development – Prototype

The Stanford Plasma Physics lab developed truck sized prototype that is currently being used to produce PFN for field trials. Small field studies began at the Siebel Varsity Golf Training Complex. Following these and laboratory studies on turf grass, we have expanded to larger field studies, most recently, field studies on lettuce in Salinas Valley, where we have demonstrated substantial increases (250%) in marketable lettuce yields, and vastly improved field holding capacity.

Applications

- Agriculture nutrient management and fertilizer

- Water sterilization

- Chemical synthesis

Advantages

- No CO2 emissions

- More energy efficient, cold plasma process than dominant combustion-based Haber-Bosch process and air-arc based (thermal plasma) Birkeland-Eydes processes.

- Massively scalable and low cost - can be run during off hours when electricity is less expensive, stored, and then fed into watering system.

- Versatile and effective - continuous or on/off process; portable with distributed units for local generation; and produces concentrated or dilute outputs.

- Near zero carbon footprint when powered from renewable sources.

Publications

- Sze, C., Wang, B., Xu, J., Rivas-Davila, J., & Cappelli, M. A. (2021). Plasma-fixated nitrogen as fertilizer for turf grass. RSC advances, 11(60), 37886-37895.

- Wang, B., Hu, Q., Castillo, B.F., Simley, C., Yates, A., Sharbono, B., Brasier, K., and Cappelli, M.A. (2023), Hort Technology, Plasma fixated nitrogen improves lettuce field holding potential (in review)

Related Links

Similar Technologies

-

Fully Water-Soluble, Fluorescence-Based, Synthetic Small-Molecule Hydrazine Sensor for Liquid Analysis S17-114Fully Water-Soluble, Fluorescence-Based, Synthetic Small-Molecule Hydrazine Sensor for Liquid Analysis

-

Eco-friendly method that produces ammonia and urea for fertilizer and other uses S22-335Eco-friendly method that produces ammonia and urea for fertilizer and other uses

-

Frequency-Selective Power Amplifier for Greener Fertilizer Production and More S22-108Frequency-Selective Power Amplifier for Greener Fertilizer Production and More