Docket #: S23-458

An Extrudable Biomaterial with Heat-Resistant Bioactivity and Tunable Degradation

Researchers at Stanford University have formulated a novel biomaterial suitable for three-dimensional (3D) bioprinting: a homogeneous composite of polycaprolactone (PCL), gelatin, and beta-tricalcium phosphate.

The 3D bioprinting technology uses biomaterials and cells to construct functional 3D structures with potential applications as tissues, organs, or drug delivery vehicles. Polylactic acid (PLA) and poly(lactic-co-glycolic acid) (PLGA) are commonly used for bioprinting due to their mechanical integrity and biodegradability, but they pose a risk of an inflammatory response as their acidic degradation byproducts accumulate. PCL, another robust biodegradable biomaterial, produces fewer acidic byproducts. It is a promising alternative when blended with gelatin, which has fast degradation kinetics. Although Homogeneous PCL gelatin (PG) blends have been made before using electrospinning, the resulting products were limited in geometry and lacked consistency in fiber quality.

Stanford researchers have devised a methodology to fabricate a more versatile homogeneous PG composite with tunable degradation kinetics and high biocompatibility. Gelatin nanoparticles embedded in this composite can be taken up by cells to enhance proliferation and differentiation. This bioactivity persists even after repeated exposure to high temperatures (>100 °C). Therefore, the new PG composite can be extruded into bioactive 3D filaments to be used for a variety of biofabrication applications.

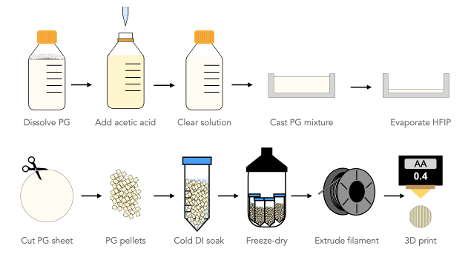

Figure 1. PG composite processing for 3D printing.

Stage of Development

The researchers have completed in vitro assessments of cell proliferation and toxicity and in vivo implantations in rats to establish safety and efficacy.

Applications

- Regenerative medicine research

- Drug testing

- Bone grafting

- Tissue repair

- Controlled-release drug delivery

- Biocompatible implants

Advantages

- Biocompatible – limited immunogenicity

- Fast and tunable degradation

- Contains gelatin nanoparticles that aid cell proliferation and differentiation

- Can withstand repeated exposure to high temperatures while retaining bioactivity

- Can be processed into bioactive 3D filaments for extrusion-based bioprinting

- High customizability in final construct geometry

- 3D reconstructions

- Porous scaffolds

- Meshes

- Thin films

Publications

- None

Related Links

Similar Technologies

-

Injectable and Stable Hydrogels with Dynamic Properties Modulated by Biocompatible Catalysts S16-344Injectable and Stable Hydrogels with Dynamic Properties Modulated by Biocompatible Catalysts

-

Injectable Supramolecular Hydrogels for Bioprinting, Wound Healing, and Drug Delivery S20-136Injectable Supramolecular Hydrogels for Bioprinting, Wound Healing, and Drug Delivery

-

Customizable, Porous Tissue Engineering Scaffold for 3D Cell Proliferation S12-089Customizable, Porous Tissue Engineering Scaffold for 3D Cell Proliferation