Docket #: S19-225

Manufacturing of Composite Grid/Core/Skin Structures

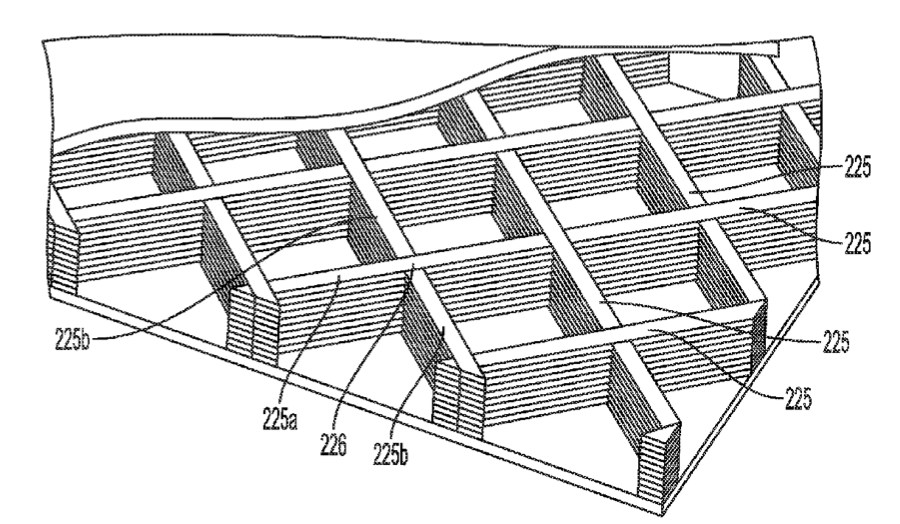

Stephen Tsai and researchers at Stanford University's Structures and Composite Laboratory have designed a composite grid-stiffened skin structure, which is ultra-lightweight, stiff, strong, and easier and less expensive to manufacture. This construction can be made in one piece, with no fasteners, fully interlocked and outside of autoclave, and can replace the conventional three-piece spar/rib/skin structure. One unique feature of the grid is the use of finite length ribs placed in a staggered pattern, so all ribs have same dimensions and height to provide high stiffness and structural integrity.

Figure 1 Grid/Skin Structure

Image courtesy Stephen Tsai

Instead of using continuous tape mixed with discontinuous inserts, Tsai's new manufacturing method uses discontinous tape with length twice that between joints. The design lowers cost, has less waste, is ultra-light, tough, and strong. Its open structure ensures that inspection and repair will be easy. The grid/skin structure is suitable for a wide range of lightweight, strong structures including aircraft, space launch vehicle bodies, rockets, automotive panels, and battery cases.

Figure 2 Tsai's designed panel (MTorres manufactured) at Paris Air Show 2019.

Photo courtesy Stephen Tsai

Stage of Development – Proof of Concept Prototype

Tsai's design is ready for application and can be modified for a variety of load cases. Design and experimental iterations are ongoing and include comparison between the new finite length ribs versus continuous tape with discontinuos inserts in flat as well as curved and full barrel panels. For the 2019 Paris Air Show, MTorres manufactured Tsai's designed panel via resin infusion of dry carbon fibers (figure 2). It can also be fabricated using traditional thermoset prepreg. The proposed grid/skin construction is better than traditional isogrid for having only two rib directions instead of three, joint and ribs with the same height, and automated layup.

Applications

- Aircraft fuselage, wings, tails, doors, bulk heads, floor panel, baggage, toilets, galley

- Rockets, cylinders, adapters, fairing, skirts

- Thermoplastics for cars

- Railroad cars for passengers and freight

- Ships

- Sporting goods

Advantages

- Ultra-light weight and stiff- weighs less than 30 percent of aluminum with equal strength and damage tolerance

- Reduced manufacturing cost and waste

- Automated production feasible - easier to produce than current manufacturing methods

- Open structure for easy inspection and repair

- Honeycomb core can be added to ribs to reduc weight and cost, and increase flexrual sitffness to weight ratio

Publications

- Tsai, Stephen. "Composite structures containing finite length tapes and methods for manufacturing and using the same." Patent application WO2020252126A1. Published 17 December 2020. https://patents.google.com/patent/WO2020252126A1

- Sloan, Jeff. "Grid/Skin Structures Explained." CompositesWorld , 1 July 2019: https://www.compositesworld.com/products/gridskin-structures-explained

- Sloan, Jeff. "2019 Paris Air Show: Highlights." CompositesWorld, 25 June 2019: https://www.compositesworld.com/articles/2019-paris-air-show-highlights

- Tsai, S., et al. "Composite double-double and grid/skin structures." International Paris Air Show (2019).

Related Links

Patents

- Published Application: WO2020252126

Similar Technologies

-

All-solid-state lithium metal battery based on three-dimensional structural design S17-133All-solid-state lithium metal battery based on three-dimensional structural design

-

Thermoresponsive Material to Prevent Battery Fire S15-458Thermoresponsive Material to Prevent Battery Fire

-

Stable cycling of lithium sulfide cathodes through strong affinity with multifunctional binders S12-346Stable cycling of lithium sulfide cathodes through strong affinity with multifunctional binders