Docket #: S17-108

Methods for High Performance Clamp-on Ultrasonic Flow Meter – Leaky Lamb Waves

Engineers in Prof. Khuri-Yakub's laboratory have developed ultrasonic methods for non-invasive flow meters to accurately measure flow rate, pressure, velocity and other parameters of gas or liquid traveling through a pipe. The technology employs ultrasound transducers clamped on to an existing pipe to detect flow by analyzing acoustic waves or vibrations, with specific methods for:

a) collectively exciting and receiving a large spectra of circumferential modes in the pipe and recording information on frequency/mode-dependent leak rates (Stanford Docket S17-107); and

b)selectively exciting guide waves in the pipe and recording information on leaky Lamb waves, which are a function of the frequency, moving fluid in the pipe, its velocity, and its direction (Stanford Docket S17-108).

The acoustic signals from both of these techniques can then be used to estimate flow rates through analytical, computer based or machine learning algorithms. Because these flow meters are clamped on, without cutting the pipe, they are ideal for permanent installations where hygiene, continuous operation, maintenance and cost are a major consideration, as well as in temporary use, as a tool for checking, servicing and maintaining existing flowmeters. These high-performance sensors could have end user applications in the oil and gas and chemical industries.

FIGURES:

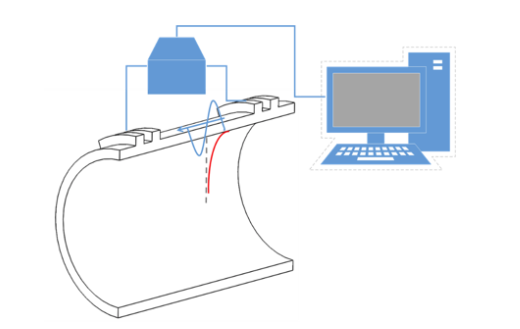

Figure 1: Leaky Lamb flow metering setup, consisting of the pipe and an instrument to monitor the effect of the flow on leakage of the guided waves.

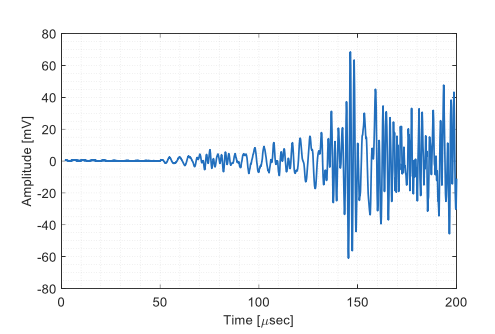

Figure 2: . Water flow measurement using the leaky Lamb wave technique. The plot shows the difference waveform of a 10 GPM flow and static water. The difference amplitude emanates from the leaked wave energy.

Stage of Research

The inventors have built prototypes of both the circumferential resonance sensor and the leaky Lamb wave sensor using piezoelectric transducers bonded to steel pipe. They used these prototypes to measure flow rates of gas (air) and liquid (water).

Applications

- Ultrasonic flow meter - clamp-on meter to measure velocity and flow profiles of liquid or gas in pipes with end-user applications in oil and gas, chemical, food, and semiconductor industries

Advantages

- Non-invasive clamp-on metering - no need to cut the pipe

- simplified installation without complex manual alignment of the transducers or input of a variety of setup parameters

- can be used for temporary, semi-permanent or permanent measurement

- hygienic - does not introduce contamination, leakage, fouling, pressure drops or energy losses

- enables continuous operation

- High performance:

- improves the accuracy and repeatability with changing temperature, density, and composition, reducing maintenance needs

- high sensitivity to the flow velocity with a wide dynamic range (from very slow to very fast flow)

- clamp on sensor comparable to inline (i.e., wetted/invasive) sensors in terms of performance and applications

- Versatile sensing:

- can measure other flow characteristics such as pressure, temperature, and composition (unavailable on current clamp-on meters)

- measures both liquid and gas flows

- enables accurate measurement of both laminar and turbulent flows, across a wide range of flow speeds

Related Links

Patents

- Issued: 11,293,791 (USA)

Similar Technologies

-

Methods for High Performance Clamp-on Ultrasonic Flow Meter - Circumferential Resonance S17-107Methods for High Performance Clamp-on Ultrasonic Flow Meter - Circumferential Resonance

-

Thermoacoustic imaging for handheld medical diagnostic and security screening applications S14-053Thermoacoustic imaging for handheld medical diagnostic and security screening applications

-

Ultrasound for Detecting and Suppressing Epileptic Seizure S18-336Ultrasound for Detecting and Suppressing Epileptic Seizure