Docket #: S23-212

Modular system for the production of degradable and recyclable thermosets via photopolymerization

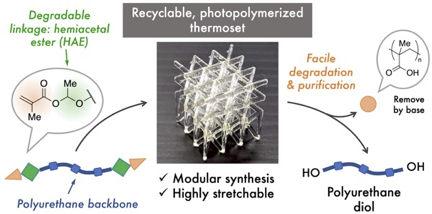

Stanford researchers in the Bao Lab have developed a flexible and modular system for the production of degradable and recyclable thermosets via photopolymerization and 3D printing of hemiacetal ester-based resins. This approach centers on a polyurethane structure known for its strong, elastic, and adjustable features. The system also incorporates methacrylate at the ends of the chains for the polymerization process and integrates hemiacetal ester (HAE) connections. These HAE connections not only bind the polyurethane and methacrylate parts but also make it easy to degrade the material with a mild acid. A significant advantage of this method is that the resulting polymer can be easily purified (through a base-driven process to remove the polymethacrylic acid side product) to recover a functional polyurethane diol, making the material not just degradable but also recyclable.

Figure

Image credit - DOI:10.1039/D3SC03623E

Stage of Development

Applications

- 3D printing applications using recyclable and degradable plastic

Advantages

- Sustainable – reduces plastic waste

- Degradable and recyclable

- Modular design- This invention focuses on polyurethane made from polypropylene glycol diol and isophorone diisocyanate, but can be expanded to incorporate any oligomeric diol/diamine and diisocyanate.

- Tunable - The molecular weight and ratio of diol/diamine to diisocyanate can be tuned to adjust crosslink density and H-bonding density.

- High stretchability and flexibility

Publications

- Wu, You-Chi Mason, Gloria Chyr, Hyunchang Park, Anna Makar-Limanov, Yuran Shi, Joseph M. DeSimone, and Zhenan Bao. "Stretchable, recyclable thermosets via photopolymerization and 3D printing of hemiacetal ester-based resins." Chemical Science 14, no. 44 (2023): 12535-12540.

Related Links

Similar Technologies

-

Mutant strains of S. cerevisiae with improved heterologous secretion of fungal lignin-degrading heme peroxidases S20-111Mutant strains of S. cerevisiae with improved heterologous secretion of fungal lignin-degrading heme peroxidases

-

Biomimetic Sorbents for CO2 Capture S12-500Biomimetic Sorbents for CO2 Capture

-

Drug Release Controlled by External Electric Field S10-297Drug Release Controlled by External Electric Field