Docket #: S22-319

Transparent Conducting Oxide Sourced Lift-Off Scribing Method for Enhancing Electrical Contact and Material Removal in P2 and P3 Scribes of Thin Film (Perovskite) Photovoltaic Technologies

Stanford inventors have developed a method for manufacturing perovskite solar modules at lower cost and greater device stability by utilizing a novel transparent conducting oxide (TCO) lift-off scribing method.

Hybrid organometallic lead-halide perovskite solar cells are an emerging thin film solar technology with the potential for lower cost production and increased performance relative to conventional silicon modules or currently available thin film technologies. However, the current methods for creating these next-generation solar modules consists of a complex multistep laser scribing process requiring multiple laser sources across multiple layers of the starting material.

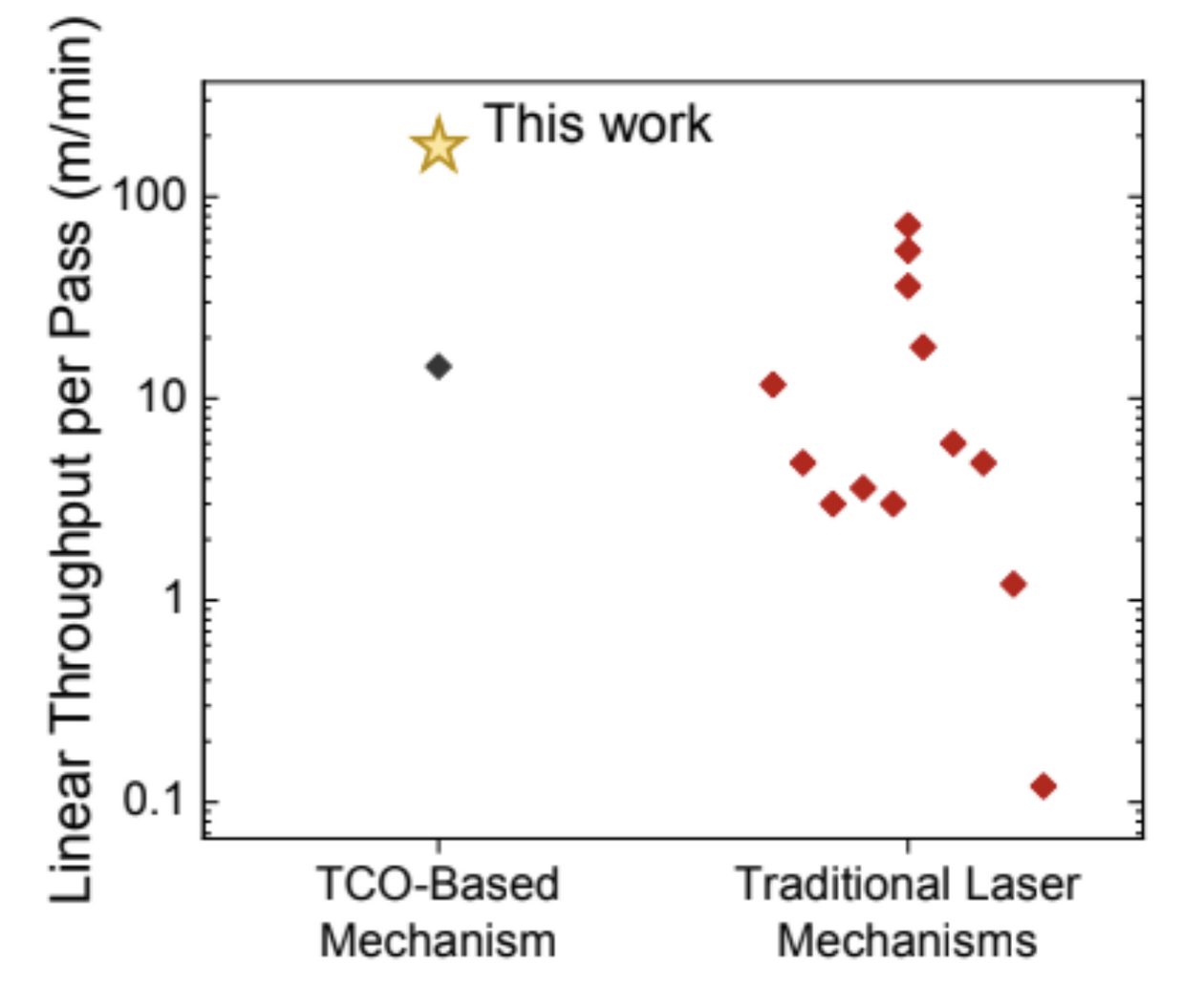

In this work, Stanford engineers describe a streamlined process for scribing perovskite solar cells using a TCO-based liftoff mechanism that relies solely on laser absorption in the front transparent electrode material, reducing thermal damage to the overlying layers and allowing for fast scribing speeds with low-cost ?s-pulse duration fiber laser systems. Demonstrating > 3 m/s processing speeds, TCO-based liftoff provides the highest throughput laser scribing method for thin-film photovoltaic devices produced on glass/TCO substrates, capable of processing large-area perovskite solar modules at a manufacturing scale.

Figure Description: Figure Description: This method of scribing compared to other methods of scribing solar modules, showing an increased throughput for this technology. (Image credit: Inventors)

Stage of Development

Ready for commercial deployment

Applications

- Manufacturing of perovskite solar panels

Advantages

- 2.5x Faster - Indirect lift-off method enables microsecond-pulse laser scribing for high-throughput production (180 m/min scribe speeds)

- Scalable

- Less residual thermal damage as a result of the scribing process

- Tunable to a number of different substrate, transparent conducting oxide, and transport layer materials

Related Links

Similar Technologies

-

Scaffold-reinforced perovskite compound solar cells S16-407Scaffold-reinforced perovskite compound solar cells

-

Ultrafast, scalable fabrication of mechanically robust perovskite films S16-376Ultrafast, scalable fabrication of mechanically robust perovskite films

-

Alloyed halide double perovskites as solar-cell absorbers S17-075Alloyed halide double perovskites as solar-cell absorbers