Docket #: S20-040

Composite laminate tapering method for more efficient design

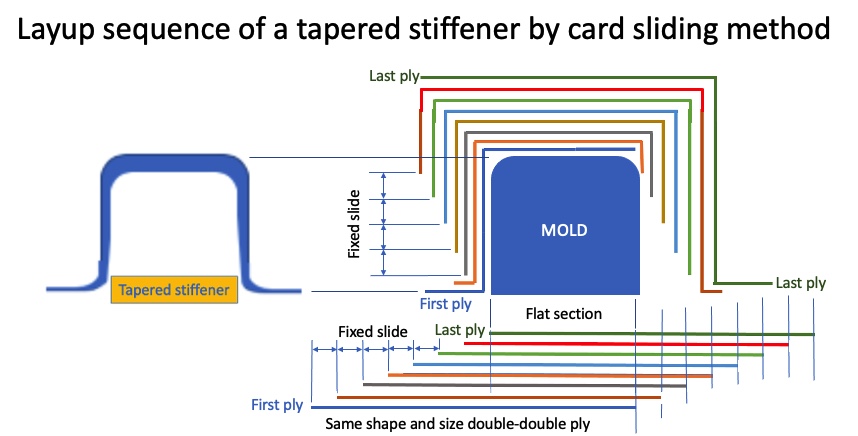

Composite laminates can be lighter, stronger and lower cost if tapering is applied to remove laminate thickness in areas not heavily loaded. To this end, Stephen Tsai and his team have developed a new tapering strategy using efficient "double-double" (DD) laminates (previously disclosed in Stanford docket S17-103). Such DD building block is 4-ply thick and can slide to form a desired taper like a deck of cards. The current building blocks are 10 or more times thicker. It cannot slide because it is too thick like sliding bricks. If individual plies are removed, the laminate properties will change. Thus sliding strategy is great to reduce weight and easy to accomplish unless it is thin like cards. With DD this would be perfect because each layer is engineered to have the desired property and form a stack of identical layers like a deck of cards, ready to slide. With this method, each ply in the laminate has the same or, dimensions, shape and size (instead of different sizes for each ply in the current conventional method). Taper is controlled by the degree of sliding of each ply. The resulting tapered beam or panel will be stiff, strong, easily laidup, with minimum scrap. Additionally, it will be lower weight and cost due to 4-ply thick tDD building block and will be less prone to error, wrinkle, warpage and delamination.

Stage of Development

Applications

- Aircraft materials such as skins for fuselage, wings, bulkhead, and floor panel

- Cars, trucks and buses such as panels and floors

- Construction materials such as panels for floors, deck, and roof

- Sports Equipment such as boards, skis, oars

Advantages

- Tapering saves weight, material, scrap, labor and can be a very fast process

- Uses double-double laminates which is simpler to design and manufacture, and stronger and lighter

- Lower cost in layup and manufacturing overall.

- Uniform ply in the laminate has the same dimensions and size

- Homogenized laminate with thin plies are delamination resistant and designed just like metals

Publications

- Vermes, Bruno, Stephen W. Tsai, Aniello Riccio, Francesco Di Caprio, and Surajit Roy. "Application of the Tsai's modulus and double-double concepts to the definition of a new affordable design approach for composite laminates." Composite Structures 259 (2021): 113246.

Related Links

Patents

- Published Application: WO2021188783

- Published Application: 20230075583

- Issued: 12,005,682 (USA)

Similar Technologies

-

Revolutionary composites technology can reduce weight and cost by 50 percent S09-227Revolutionary composites technology can reduce weight and cost by 50 percent

-

Pre-Plied Double-Double (PPDD) Laminated Composite Tape with Short Fiber S25-117Pre-Plied Double-Double (PPDD) Laminated Composite Tape with Short Fiber

-

Manufacturing of Composite Grid/Core/Skin Structures S19-225Manufacturing of Composite Grid/Core/Skin Structures