Docket #: S14-006

Nanoscale Interfacial Engineering with Interconnected Hollow Carbon Nanospheres for Stable Lithium Metal Anode

Stanford researchers led by Profs. Yi Cui and Steven Chu have demonstrated that interfacial layer of hollow carbon nanospheres allows stable lithium metal anode cycling up to a practical current density of 1 mA cm-2. The cycling Coulombic efficiency is improved to ~99 % for more than 150 cycles. These results indicate that nanoscale interfacial engineering could be a promising strategy to address the intrinsic problems of lithium metal anodes.

This invention is envisioned as a new, low cost battery design that can enable next generation high energy density systems such as Li-S and Li-O2 batteries for portable electronics, electric vehicle and stationary energy storage systems.

News Articles

Stanford News, Jul. 29, 2014, “Stanford researchers seek 'Holy Grail' in battery design”

The Atlantic, May 2014, “A Better Battery”

Forbes, July, 29, 2014, "Battery Life 'Holy Grail' Discovered. Phones May Last 300% Longer"

Stanford Daily, Aug. 9, 2014, “Researchers take major step towards longer battery life”

The Economist, Sep, 13, 2014, "Caging the Li-ion "

Stage of Research:

Figure:

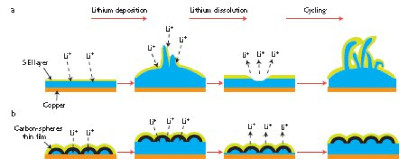

Figure description-Schematic diagrams of the different Li anode structures. a, A thin film of SEI layer forms quickly on the surface of deposited Li (blue). Volumetric changes during the Li deposition process can easily break the SEI layer, especially at high current rates. This behaviour leads to ramified growth of Li dendrites and rapid consumption of the electrolytes. b, Modifying the Cu substrate with a hollow carbon nanosphere layer creates a scaffold for stabilizing the SEI layer. The volumetric change of the Li deposition process is accommodated by the flexible hollow-carbon-nanosphere coating.

Applications

- Lithium metal anode and potentially other pure metal anodes used in batteries

- High density lithium batteries systems such as lithium sulfur and lithium air batteries can be realized due to this lithium metal anode

- Such batteries will be very attractive for portable electronics, electric vehicles and stationary energy storage systems

Advantages

- High efficiency of charge/discharge on long cycle life for lithium metal battery

- Enables low cost, high energy density battery systems such as Li-S and Li-O2 batteries

- Unique material provides excellent protection for the lithium anode - amorphous carbon thin film coating is chemically and mechanically stable when in contact with the lithium anode

- Addresses current limitations of using lithium metal anodes - Lithium is attractive due to its high specific capacity and low anode potential but suffers from formation of dendritic and mossy metal deposits causing safety issues and low Coulombic efficiency during charge/discharge cycles

Publications

- G. Zheng, S. W. Lee, Z. Liang, H.-Y. Lee, K. Yan, H. Yao, H. Wang, W. Li, S. Chu and Y. Cui, Interconnected hollow carbon nanospheres for stable lithium metal anodes, Nature Nanotechnology (2014).

- K. Yan, H.-W. Lee, T. Gao, G. Zheng, H. Yao, H. Wang, Z. Lu, Y. Zhou, Z. Liang, Z. Liu, S. Chu, and Y. Cui, "Ultrathin Two-Dimensional Atomic Crystals as Stable Interfacial Layer for Improvement of Lithium Metal Anode," Nano Letters 2014 14 (10), 6016-6022.

Patents

- Published Application: 20160013462

- Issued: 10,256,448 (USA)

Similar Technologies

-

Highly Conducting Solid Electrolytes for Batteries S15-203Highly Conducting Solid Electrolytes for Batteries

-

Spinel Nanocrystals on Graphene S11-094Spinel Nanocrystals on Graphene

-

Nanocarbon/Inorganic Nanoparticle Hybrid Materials for Energy Storage and Fuel Cells S09-371Nanocarbon/Inorganic Nanoparticle Hybrid Materials for Energy Storage and Fuel Cells