Docket #: S23-326

High Density Soft Bioelectronic Fibers

Stanford researchers have developed a method for manufacturing high quality multifunctional soft electronic fibers based on conventional microfabrication techniques.

Electronic fibers, with electronic components integrated into one-dimensional form, present a wide range of opportunities for applications across various fields, from consumer electronics to healthcare and more. Their unique one-dimensional structure allows for more compactness and deformability compared to 2D and 3D systems. Unfortunately, currently available electronic fibers are manufactured through complex processes, such as fiber spinning, 3D printing, microfluidics, and thermal drawing. As a result, they suffer from bulkiness, rigidity, and low density and imprecise positioning of active components.

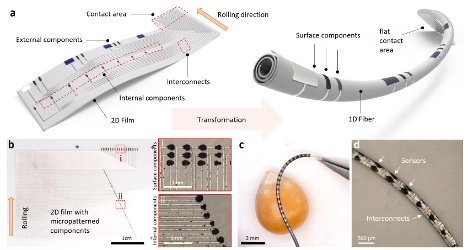

Stanford researchers have devised a strategy to manufacture high density and versatile electronic fibers by transforming microfabricated 2D films into 1D fibers using spiral transformation. This approach takes advantage of well-established microfabrication techniques developed for planar substrates, simplifying the manufacturing process while giving precise control of positions of the active components. The researchers have demonstrated that centimeter-scale 2D thin films with micro-patterned components can be rolled into micro-scale electronic fibers. They have successfully built and tested electronic fibers for gastrointestinal monitoring/stimulation and neural recording. This new manufacturing method can make electronic fibers more accessible for a wide range of applications.

Figure Caption: 2D-to-1D transformed fiber

Applications

- Probes

- Guidewires

- Pacemakers

- Deep brain stimulation

- Neural recording

- Smart biopsy needles

- Electronic sutures

- Electronic textiles

- Soft robotics

- Wearables

- Sensors

Advantages

- High density

- Thin

- Flexible

- Precise control over the positions of components

- Can be multifunctional

- Compatible with conventional microfabrication techniques

Publications

- Khatib, M., Zhao, E.T., Wei, S. et al. High-density soft bioelectronic fibres for multimodal sensing and stimulation. Nature 645, 656–664 (2025). https://doi.org/10.1038/s41586-025-09481-2

- Khatib, M., Zhao, E. T., et al. (2023). "Spiral NeuroString: High-Density Soft Bioelectronic Fibers for Multimodal Sensing and Stimulation." bioRxiv, 2023.10.02.560482.

Related Links

Similar Technologies

-

Electrochromic Resistive Pressure Sensor S15-225Electrochromic Resistive Pressure Sensor

-

Self-Powered Electronic Skin S14-211Self-Powered Electronic Skin

-

Materials, devices, and manufacturing methods for high-speed and large-scale intrinsically stretchable electronics S22-399Materials, devices, and manufacturing methods for high-speed and large-scale intrinsically stretchable electronics