Docket #: S21-046

Nanotextured Metal Powders for 3D Printing

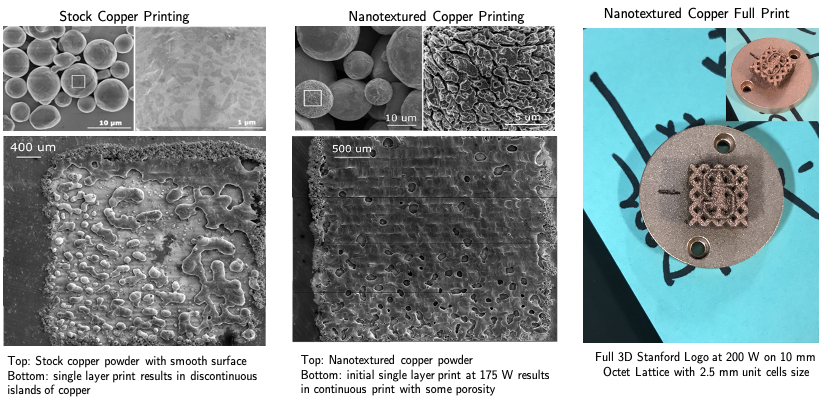

Researchers at Stanford have developed a process for modifying metal powder stock to enable printing of high reflectivity metals using moderate laser powers (200-400 W) in commercially available printing systems (200-400W). These are the most ubiquitous types of laser-based 3D printing systems and do not require high vacuum or specialized optics. This process will enable 3D printing of high purity copper and other metal structures using laser-based metal 3D printing systems. Currently, state of the art metal 3D printing, or additive manufacturing, is limited to a small library of printable metals (e.g., stainless steel, Ti alloys, etc). There is a demand for the ability to reliably print high purity copper, silver, gold and platinum for thermal and electrical conductivity applications. Conventionally, these materials are difficult to 3D print due to their high laser reflectivity (low absorption) during the printing process. The new method produces surface-modified metal powders to improve laser absorptivity and printability. This can be done using a technique such as wet chemical, electrolytic or physical etching to create a nanotextured surface.

Comparison of stock and nanotextured copper powder and printing demonstration of lattice (image credit: the inventors)

Stage of Development

The researchers have demonstrated continuous printing of copper structures. Next steps include process optimization, simulations and fundamental measurements of absorptivity.

Applications

- Production of powder feedstock for 3D printing of copper and other highly reflective metals

- Thermal management applications (server farms maintained by tech companies)

- Automotive and aerospace industry

- Healthcare industry (e.g., antimicrobial equipment)

Advantages

- Efficient printing platform for a variety of hard-to-print metals

- Employs commercially available, lower laser beam powers

- Modified powder maintains flowability

Publications

- Li, Qi et al. Mechanical nanolattices printed using nanocluster-based photoresists. Science 2022, VOL. 378, NO. 6621

- CASTAÑÓN, LAURA. New nanoscale 3D printing material designed by Stanford engineers could offer better structural protection for satellites, drones, and microelectronics. Stanford News 2022

Related Links

Patents

- Published Application: 20220305553

- Issued: 11,938,536 (USA)

Similar Technologies

-

Denoising WaveY-Net: An ultra-fast, auxiliary neural network enhanced surrogate field solver S22-445Denoising WaveY-Net: An ultra-fast, auxiliary neural network enhanced surrogate field solver

-

Dual network, 3D printed pyrolytic carbon polymer structure fabrication method S23-514Dual network, 3D printed pyrolytic carbon polymer structure fabrication method

-

Spinel Nanocrystals on Graphene S11-094Spinel Nanocrystals on Graphene