Docket #: S24-169

In-situ strain probe for low-dimensional materials

Stanford University researcher, Bai Yang Wang, has designed a strain probe compatible with the Quantum Design Physical Property Measurement System (PPMS®) for in-situ strain tuning of low-dimensional materials at cryogenic temperatures under large magnetic field under vacuum. When used with PPMS® the system can reach a 2 K base temperature and magnetic field up to 12 T. The polyimide-based strain probe's in-situ camera monitors material deformation in real time which allows tuning and continuous measurement at cryogenic temperatures without breaking vacuum or warming up. The unique polyimide support can achieve larger tensile strain values (above 10%) compared to bulk samples which are limited to less than 2%. Strain symmetries and directions can be precisely aligned relative to the material's principle axes, unlike bulk-sample-based piezo-setup where the strain direction is constrained by the shape of the bulk samples. The advantages over other strain measurement approaches makes Stanford's in-situ strain probe ideal for extreme, low-dimensional materials research and characterization.

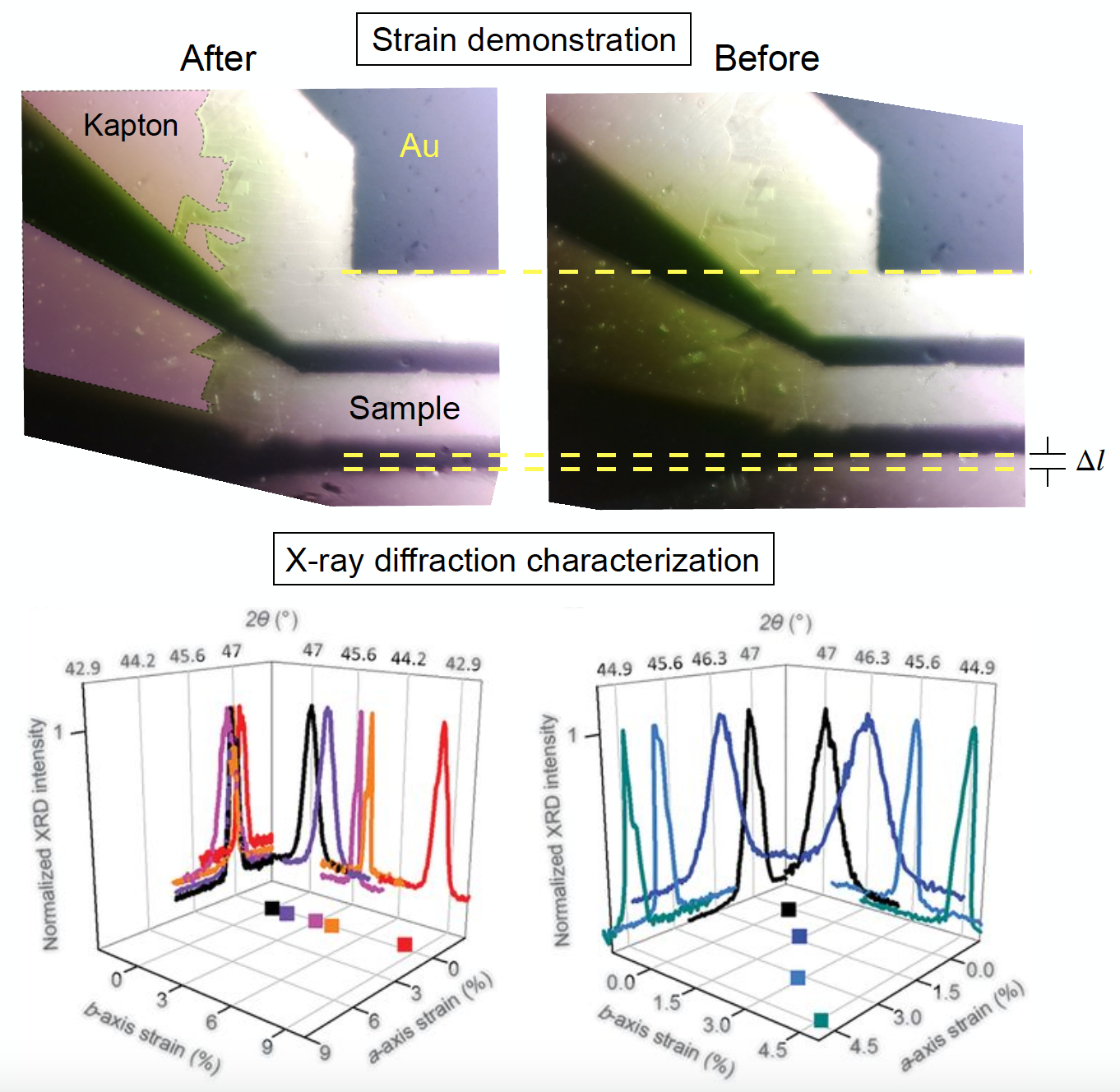

In situ strain demonstration

(Image courtesy Bai Yang Wang)

Stage of Development - Prototype

Applications

- Materials research & characterization equipment

Advantages

- Easily tunable strain symmetries and directions – can precisely align stress field relative to the material's principle axes (unlike bulk-sample-based piezo-setup, where the strain direction is constrained by the shape of the bulk samples).

- More versatile – large tensile strain can be induced into materials (unlike bulk samples limited to 2%).

- Continuous measurement and tuning under vacuum at cryogenic temperature.

- Real time monitoring with direct visualization of material deformation via in situ camera with no need for strain simulations.

Related Links

Similar Technologies

-

Breakthrough Optical Frequency Processing for Quantum Computing and Beyond S24-365Breakthrough Optical Frequency Processing for Quantum Computing and Beyond

-

Photon spin processor for on-chip classical and quantum information systems S24-212Photon spin processor for on-chip classical and quantum information systems

-

Diode-pumped photonic integrated titanium-sapphire waveguide amplifier S23-369Diode-pumped photonic integrated titanium-sapphire waveguide amplifier