Docket #: S23-336

Electrochemical reactor for ammonia reclamation from wastewater nitrate

Stanford researchers have developed an "electrocatalyst-in-a-box" that extracts wastewater nitrate and converts it into ammonia. Nitrogen pollution threatens water security and human health, and demand for ammonia continues to grow. There is an enormous need for a sustainable, electrified ammonia production from wastewater to offset carbon-intensive Haber-Bosch ammonia manufacturing.

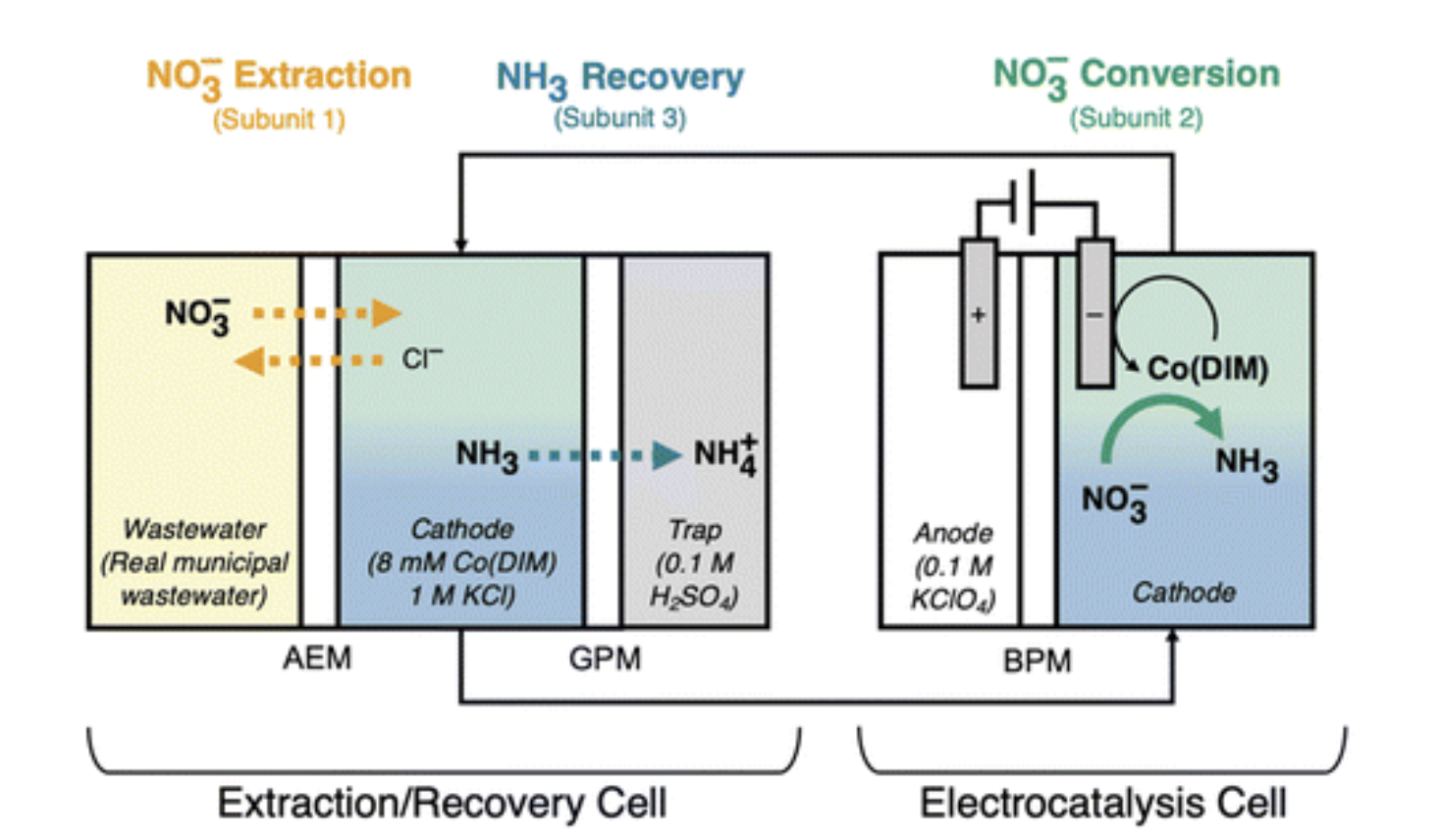

The Electrocatalyst-in-a-box (ECaB) performs three key processes: wastewater nitrate extraction, nitrate conversion to ammonia, and ammonia recovery. ECaB consists of two reactors (extraction/recovery cell and electrocatalysis cell), four recirculating electrolyte reservoirs (wastewater, catholyte, anolyte, and trap), and two applied potential conditions (open circuit and –1.05 VAg/AgCl). At small scale, it effectively and efficiently processes agriculture wastewater at atmospheric temperature and pressure. It is integrable with renewable energy sources – making it highly beneficial for sustainable environmental and industrial applications.

This technology is part of a portfolio of related inventions(S19-331, S20-348, S20-349, S23-336) that extract value from wastewater by reclaiming ammonia from nitrate-contaminated wastewater streams.

Electrocatalyst-in-a-box (ECaB) Schematic

(Image courtesy the Tarpeh Lab)

Stage of Development – Proof of Concept

Applications

- Wastewater treatment

- Ammonia production from aqueous nitrate feedstocks

- Decentralized fertilizer production

Advantages

- Energy Efficient, Sustainable, and Flexible Operation – Supports semi-batch or continuous processing, at small scale and atmospheric temperature and pressure. Can be run with renewable-powered electricity, reducing emissions associated with ammonia production.

- Broad Compatibility - Overcomes challenges from impure reactant feeds to remove nitrate and transform into useful new compounds.

- Fast Reaction Rates and Stable Catalyst, Resistant to Leaching

Publications

- Miller, D. M., Liu, M. J., Abels, K., Kogler, A., Williams, K. S., & Tarpeh, W. A. (2024). Engineering a molecular electrocatalytic system for energy-efficient ammonia production from wastewater nitrate. Energy & Environmental Science, 17(15), 5691-5705. DOI: 10.1039/D4EE01727G

- Roberts, T. (2024). William Tarpeh taps the potential of polluted water. Stanford News. https://news.stanford.edu/stories/2024/10/william-tarpeh-creativity-leads-innovative-wastewater-transformations

- Tarpeh, W. A., Senesky, D. G., Lalwani, A. V., Holliday, M., Mu, L., Clark, B. D., Liu, M.J., Dong, H., & Guo, J. (2022). U.S. Patent Application No. 17/642,902.

- Guo, J., Liu, M. J., Laguna, C., Miller, D. M., Williams, K. S., Clark, B. D., B.D., Muñoz, C., Blair, S.J., Nielander, A.C., Jaramillo, T.F., & Tarpeh, W. A. (2024). Electrodialysis and nitrate reduction (EDNR) to enable distributed ammonia manufacturing from wastewaters. Energy & Environmental Science, 17(22), 8787-8800. DOI: 10.1039/D4EE03002H

- Tarpeh, W. A., Liu, M. J., & Clark, B. D. (2023). U.S. Patent Application No. 18/041,769.

- Tarpeh, W. A., Kogler, A., Clark, B. D., Liu, M. J., & Chow, W. (2024). U.S. Patent Application No. 18/041,678.

Related Links

Patents

- Published Application: WO2025038754

Similar Technologies

-

Flexible electrochemical stripping to recover alkaline and acidic ammonia from wastewaters S20-349Flexible electrochemical stripping to recover alkaline and acidic ammonia from wastewaters

-

Electrodialysis and electrochemical nitrate reduction process S20-348Electrodialysis and electrochemical nitrate reduction process

-

Durable and Immersible Network Enabled Ammonia Sensor for Water Monitoring S19-331Durable and Immersible Network Enabled Ammonia Sensor for Water Monitoring